Surface Science

PRECISE SURFACE ANALYSIS

Ion Beams for Surface Science

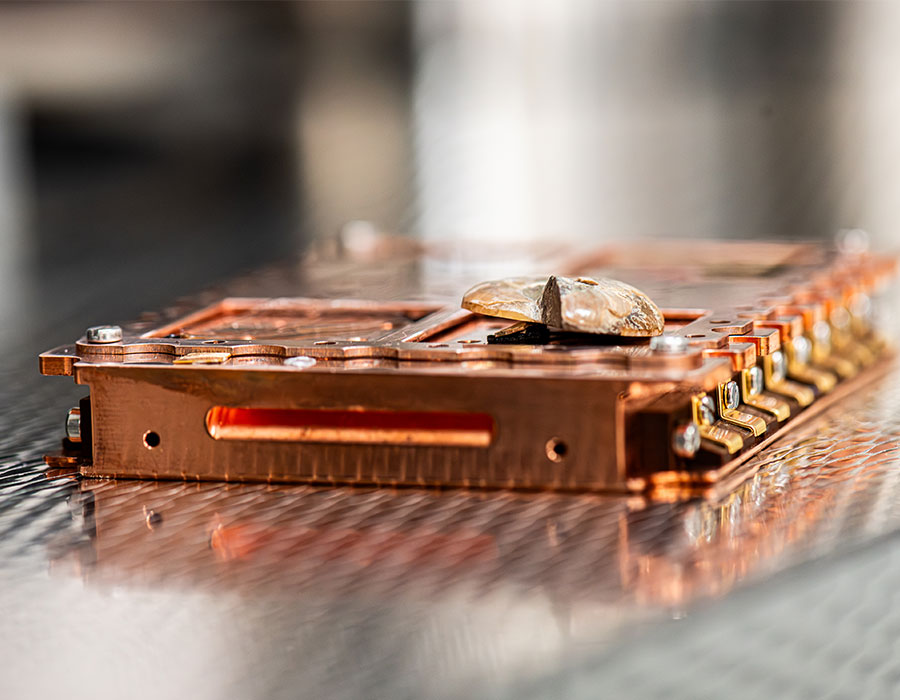

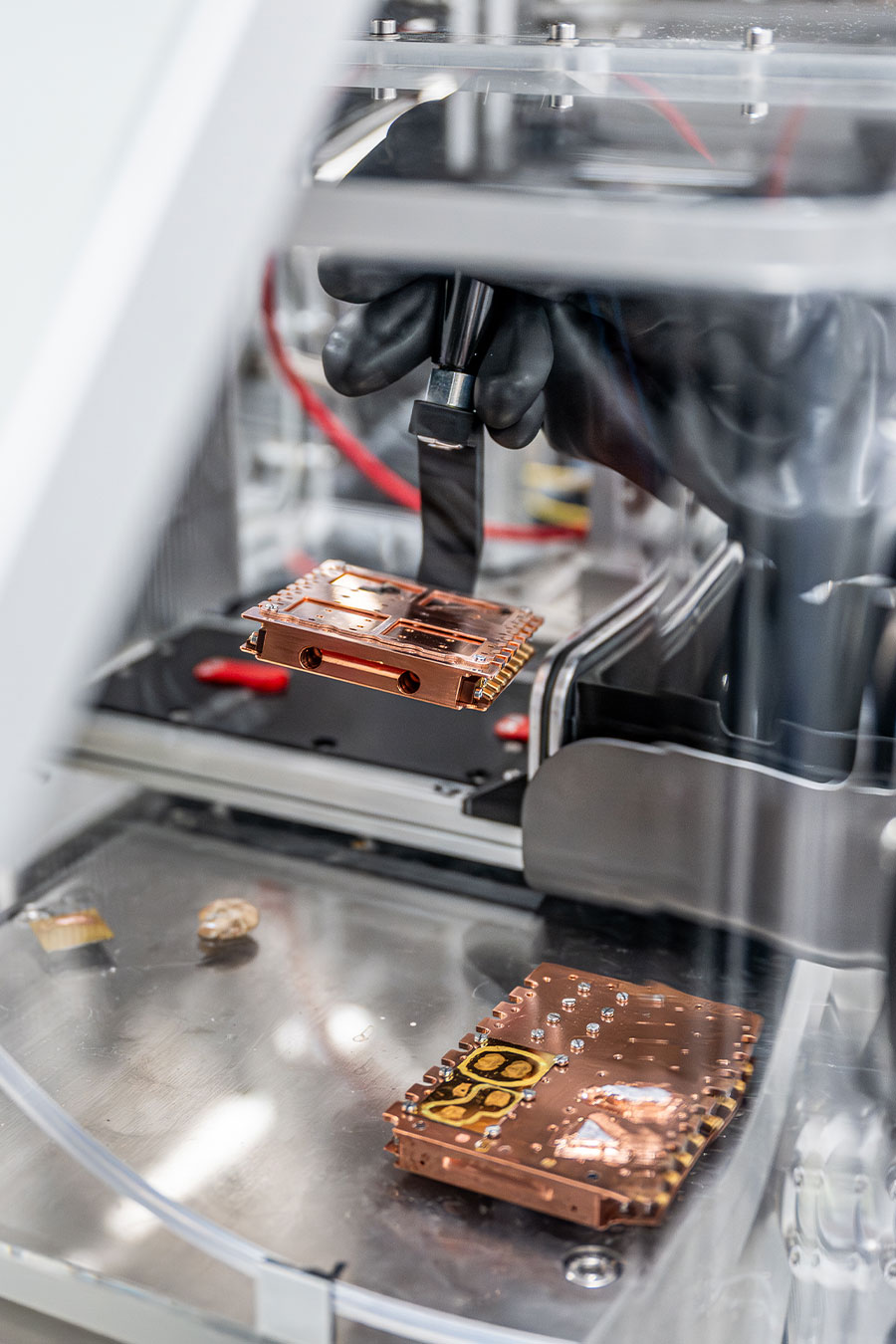

To properly study the physics and chemistry of surfaces and interfaces, you need fully clean surfaces that are free from contamination. Surface analysis techniques like Secondary Ion Mass Spectrometry (SIMS), X-Ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES), and Low Energy Electron Diffraction (LEED) all use Ion Beams to prepare surfaces for analysis or to provide the analysis itself.

LOW DAMAGE SURFACE EXAMINATION

Using Ion Beam Solutions for Surface Science

SIMS is an excellent tool for surface and interface analysis. By combining SIMS with the use of Gas Cluster Ion Beams (GCIB), the J Series III offers unique benefits. It provides analysis of highly complex samples, such as biological tissues, hybrid multi-layered materials, polymers, and samples with complex topography.

Ready to find out more about the J Series III and how it excels in surface science analysis?

REVOLUTIONARY

GCIB offers a low-damage alternative.

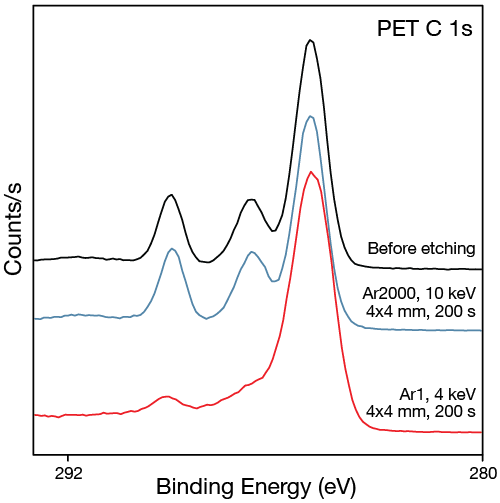

GCIB SIMS is not limited by the same factors as traditional ToF SIMS instruments that use a monoatomic beam. While such instruments are excellent for homogenous, hard materials, the damage done by the monoatomic beam at high energies is significant. This can result in inter-layer mixing, subsurface damage, and fragmentation of higher molecular weight species.

The J Series III mitigates this challenge.

By using a GCIB Analysis Beam at high total beam energy, the J Series III is able to use extremely large clusters. Commonly, these are up to 30,000 Ar or 60,000 H2O. The total beam energy is distributed over the number of atoms in the cluster, which gives versatile e / n energy that ranges from 2 to 2,000 eV.

What this means:

The large clusters enable a very low e / n. When used to bombard a surface, these:

- Significantly reduce fragmentation, easing the lifting of high molecular weight species like lipids, peptides, and small proteins.

- Reduces subsurface damage and less frequent instances of inter-layer mixing.

Follow the link below to learn more about the techniques facilitated by our Ion Beam solutions for surface physics.

THE END RESULT

3D Depth Profiling is Made Simple.

The advantages offered by our Ion Beam solutions for surface science mean that 3D depth profiling and imaging isn’t’ just possible – it’s simple. By using the GCIB as the primary beam for analysis, there is no need to clean or remove damaged layers. No etch-only cycle is needed, and all sputtered secondary ions are simultaneously sputtered and analysed. This gives rise to superior depth resolution and profiling.

Ergonomic and simple fast-etching.

The 70kV GCIB also facilitates work with smaller, dense, high-energy gas clusters at very high total beam energy. With these, it’s possible to fast etch through materials whilst reducing preferential sputtering. The smaller clusters with a higher e / n are optimal for mixed and hybrid materials like perovskites, OLEDS, and glass.

Beyond SIMS

Aside from SIMS, Ion Beams such as C60 and Gas Cluster Ion Beams ( GCIB 10S) are used in other surface science techniques, such as XPS or even DSEM, to efficiently remove organic matter from surfaces. In a process known as depth profiling, Ion Beams can also remove a volume of material, known as sputtering, revealing a fresh surface for analysis.