News

STAY UP TO DATE

News

Here, you’ll find everything from cutting-edge product developments to company announcements and industry insights. Stay informed on how we’re shaping the future of Ion Beam technology, and contributing to materials, life science and quantum research across the world.

SIMS23 Rowland Hill Awards

The 23rd secondary ion mass spectrometry (SIMS 23) conference was held in Minneapolis, MN, from 18 – 23 …

ToF SIMS – Time of Flight Secondary Ion Mass Spectrometry

What is ToF SIMS? What is it used for, and what sort of information can it provide? Which …

How the J105 SIMS works: An introductory guide

The J105 SIMS is a state-of-the-art 3D imaging ToF SIMS combining innovative design with cutting-edge science that has …

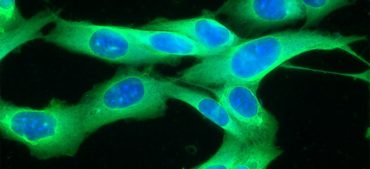

High-resolution multi-omics profiling of individual cells

In a landmark publication, Tian et al. demonstrate the feasibility of combined GCIB/C60 SIMS imaging for multi-omics profiling …

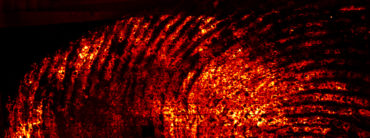

Cocaine metabolite imaging in fingerprints with Water Cluster SIMS

Detection of drug compounds and their metabolites in natural environments is a critical topic for both forensic and …

New funding boosts the UK’s future in Quantum manufacturing

Ionoptika Ltd and the University of Surrey have been awarded project grants worth a total of £425,000.00 from …