News

STAY UP TO DATE

News

Here, you’ll find everything from cutting-edge product developments to company announcements and industry insights. Stay informed on how we’re shaping the future of Ion Beam technology, and contributing to materials, life science and quantum research across the world.

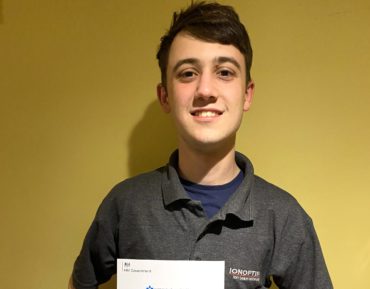

Celebrating Success: Owen’s Apprenticeship Story

Today we celebrate Owen Miles, who has successfully completed his apprenticeship with us, and now joins us as …

Employee Spotlight: Sulaiman Aminuddin – Electronics and System Test Engineer

Ionoptika is proud of its skilled and dedicated staff and today we're interviewing our customer support agent Dr …

Bright SPARQ(s) Attend Pioneering Project Meeting

In April we attended the second annual meeting of the SPARQ(s) project, marking the halfway point of our …

Employee Spotlight: Andy Wright – Production and Purchasing Manager

Ionoptika is proud of its skilled and dedicated staff and today we're interviewing our Production and Purchasing Manager …

The Rowland and Christine Hill Student Awards at SIMS-24

The 24th secondary ion mass spectrometry (SIMS-24) conference was held in La Rochelle, France from 8-13 September 2024. …

SIMS-24, La Rochelle

What an exciting week at SIMS-24, armed with our smartest exhibition stand yet, our team journeyed to La …