Gas Cluster Ion Beams

PIONEERING GLOBAL EXPERTISE

Gas Cluster Ion Beams

Gas Cluster Ion Beams (GCIBs) are incredibly versatile ion sources with an increasing number of applications. As global experts in the development of GCIBs, we offer models that are perfect both for sputtering and for analysis.

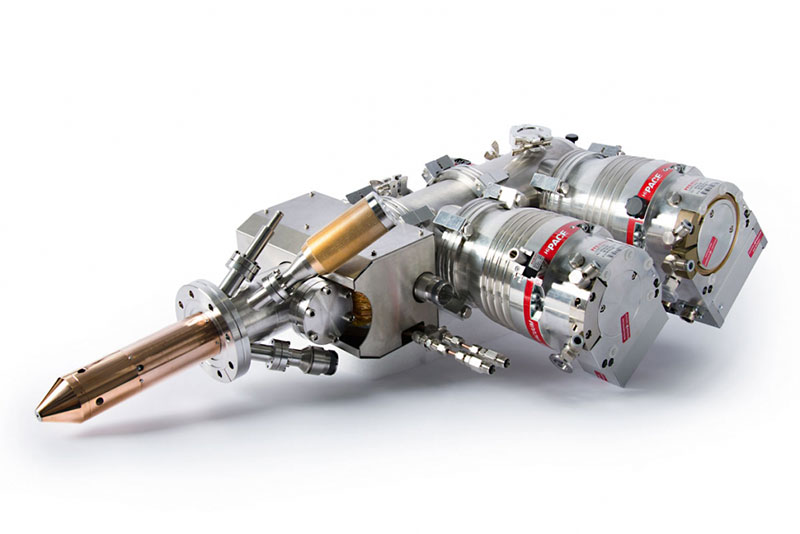

GCIB 10S

The GCIB 10S is a high-performance gas cluster Ion Beam system offering rapid, low-damage sputtering that enables superior surface analysis. It allows for precise depth profiling, which is ideal for organic and inorganic materials. Key features include real-time cluster measurement, sample current imaging, and easy integration with various high-vacuum instruments and software.

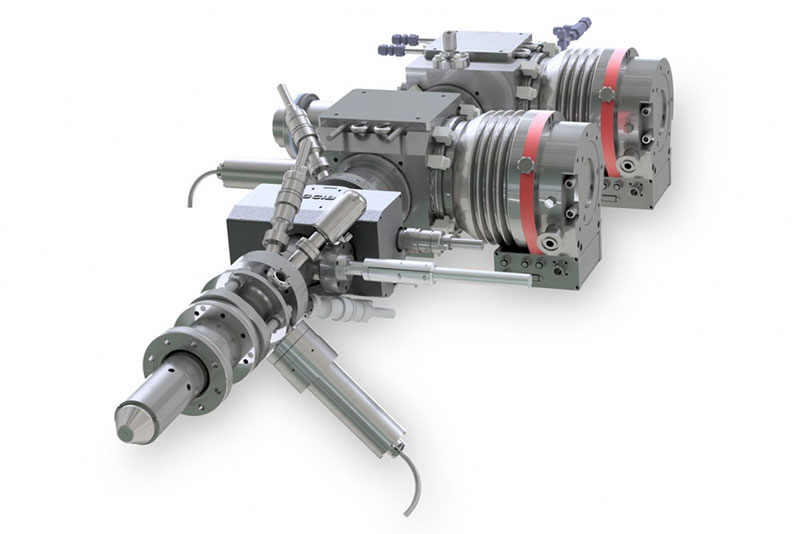

GCIB 70

The GCIB 70 is a 70 kV gas cluster Ion Beam that provides high-resolution imaging SIMS with a focused 1.5 µm spot size. It efficiently sputters organic, biological, and polymeric materials, providing unmatched sensitivity. The GCIB 70 is available exclusively on Ionoptika’s J Series III SIMS and supports various gases and cluster sizes.

Product & integration information: | GCIB 10S | GCIB 70 |

|---|---|---|

|

|

|

Want to find out more about the applications of our Ion Beams?

HOW IT WORKS

How do our GCIBs operate?

GCIBs are composed of ionised clusters of atoms or molecules formed from a gaseous source. This size of a cluster ranges from just a few hundred constituent atoms to well over 30,000. It can be formed from many different gas sources, including both inert and reactive gases.

Such large clusters lead to energy being distributed across all atoms in the cluster. The result is a very gentle sputtering effect and almost no damage to sub-surface layers.

GCIBS are hyper-effective at sputtering soft materials.

The nature of GCIBs makes them the perfect choice for sputtering organic tissue and polymers. This is in total contrast to polyatomic beams like Bi3+ or Au3+, which cause significant fragmentation of organic molecules and penetrate sub-surface regions, causing poor depth profile performance.

The way GCIBs operate.

Clusters are formed as high-pressure gas (~ 18 bar) expands into a vacuum (~10-2 mbar) through a small nozzle. Then, it expands, cools, and condenses into clusters. A jet of neutral clusters is formed, which pass through a series of apertures into a region of high vacuum where they are ionised through electron bombardment.

The clusters formed will have a distribution of sizes, the average of which will depend on various parameters, including the source gas, gas pressure, and ionisation settings. The cluster distribution can be further controlled using a Wien filter, which acts to mass-select the cluster that reaches the target.

A range of gases can be used in the GCIB, the most common of which are Ar, CO2, and an Ar/CO2 mix.