C60

INNOVATIVE, VERSATILE SOLUTIONS

C60

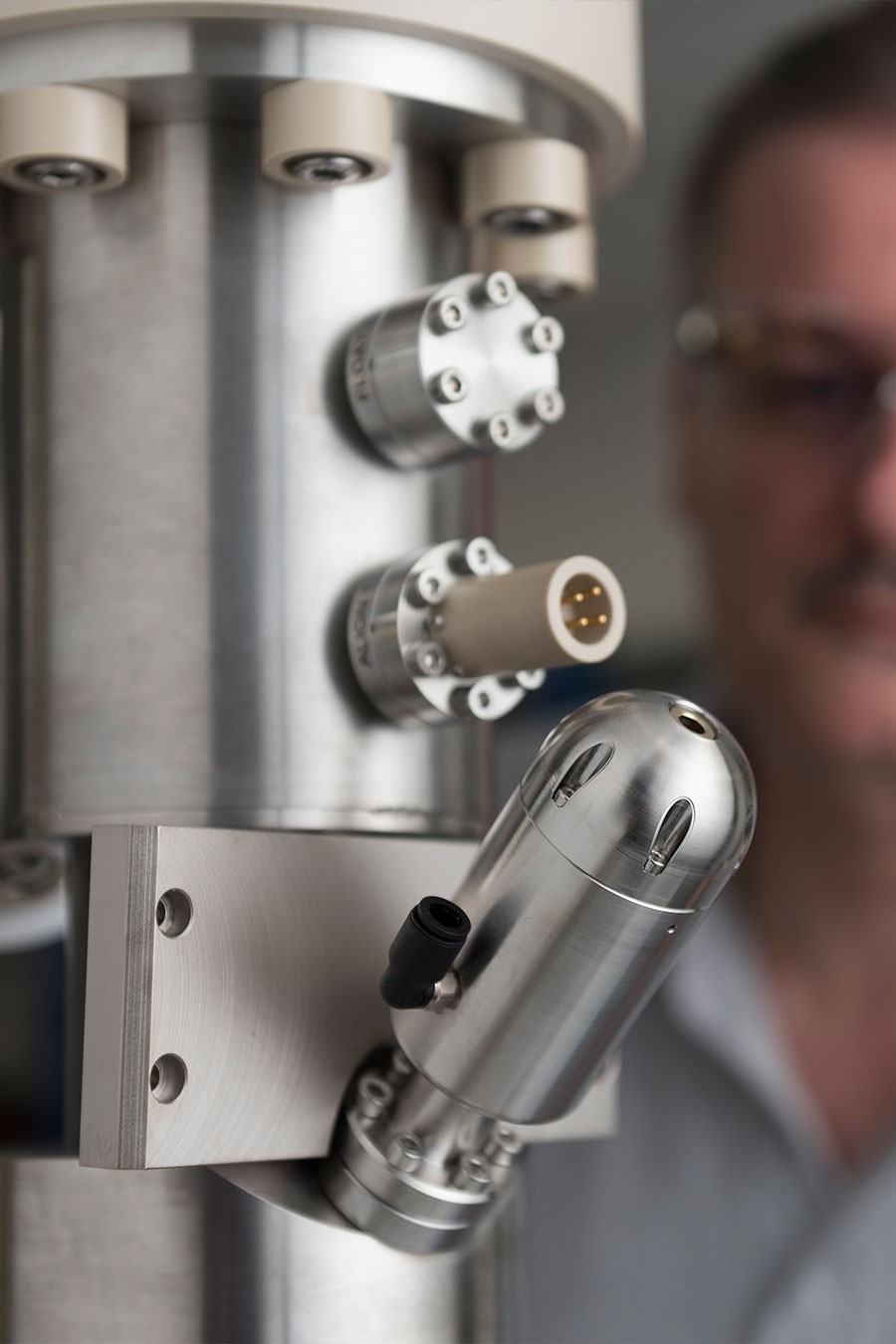

C60 Ion Beams provide excellent sputter rates on both hard and soft materials, with potential spot sizes down to 300nm. The range of beam energies and spot modes we provide support a wide range of uses.

IOG C60-20S

The C60-20S Ion Beam is designed for high-performance sputtering with minimal damage and reduced preferential sputtering. Operating at up to 20kV, it ensures effective material sputtering without carbon re-deposition. Ideal for XPS, AES, and SIMS instrument upgrades, it offers fast etching, uniform sputtering across materials, easy servicing, and long life.

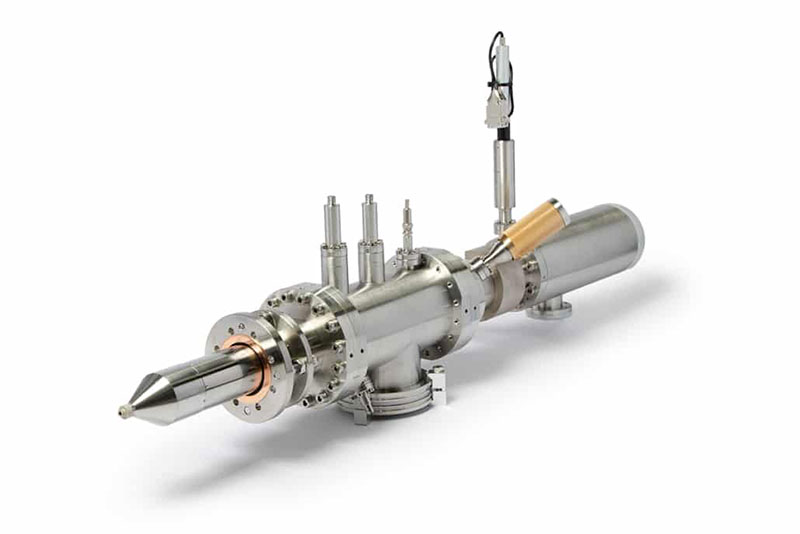

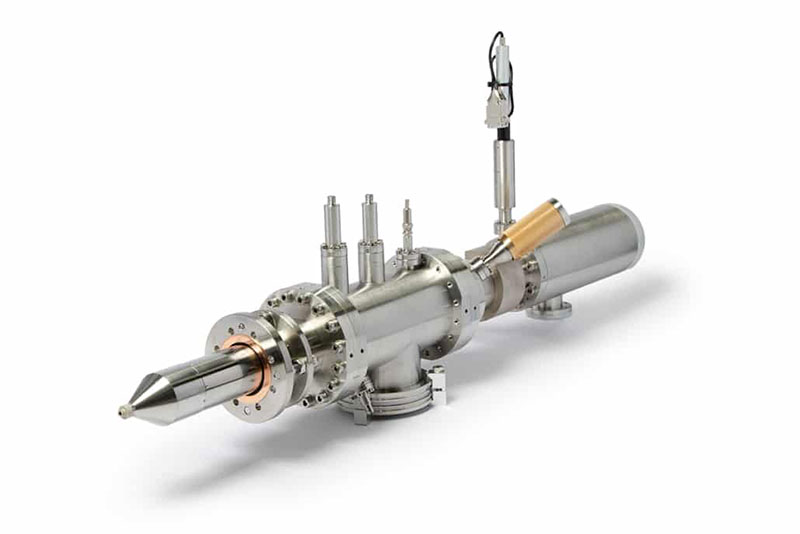

IOG C60-20

The IOG C60-20 is a high-performance 20 kV Ion Beam system for SIMS analysis of complex samples. With a 2 μm minimum spot size, it combines versatility and cost-effectiveness. Equipped with a Wien filter, it allows mass filtering and selection of charge species, features easy servicing, and has advanced pulsing capabilities.

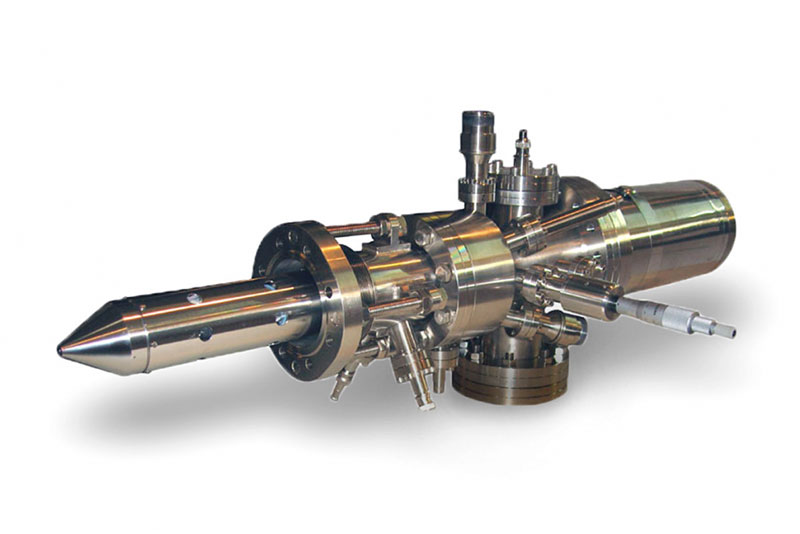

IOG C60-40

The C60-40 is a top-performing 40 kV cluster Ion Beam for molecular SIMS analysis, featuring a fine 300 nm spot size and up to 1 nA beam current. It delivers uniform sputtering, higher etch rates, and enhanced molecular yields, making it ideal for applications in biomedical, polymer science, and metallurgy.

Product & integration information: | C60-20S | C60-20 | C60-40 |

|---|---|---|---|

|

|

|

|

Want to find out more about the applications of our Ion Beams?

HOW IT WORKS

How do our C60 Ion Beams work?

C60 Ion Beams are composed of 60 carbon atoms arranged into the shape of a football. The impact of a C60 ion on a sample surface is quite different from the impact of a monoatomic ion.

The C60 molecule is larger (approximately .7 Å) than the lattice constant for most materials. This means that it does not experience channelling in the way that smaller Ion Beams, such as bismuth, do.

C60 Ion Beams exhibit extremely uniform sputter rates.

This occurs across a wide range of materials, even on challenging poly-crystalline materials where there is a range of crystal orientations.

The large molecule is unable to penetrate deeply into the sample as the momentum of each carbon atom is very low. Therefore, the energy of the incident particle is transferred to the top few monolayers of the sample only. The result is a very high sputter yield and minimal damage to the remaining material.

Low damage to the new surface and high yields of molecular ions.

This is because, according to molecular dynamics simulations, 90% of incident carbon atoms rebound from the surface during the impact.

Topographical effects are also much reduced when using the C60+ beam. The problems of matrix effects and differential sputter rates across different materials and crystal orientations are, therefore, reduced.