Ion Implantation

HIGH-PRECISION METHODOLOGY

Ion Implantation

Ion implantation is a process whereby dopant ions are accelerated in intense electrical fields to penetrate the surface of a material, thus changing the material’s properties. An essential technique in the semiconductor industry, it is used to modify the conductivity of a semiconductor during the fabrication of integrated circuits. It is also heavily used for silicon-on-insulator devices and in many other industries, including physics, materials science, and metallurgy.

INNOVATION

Innovative ion implantation system suppliers.

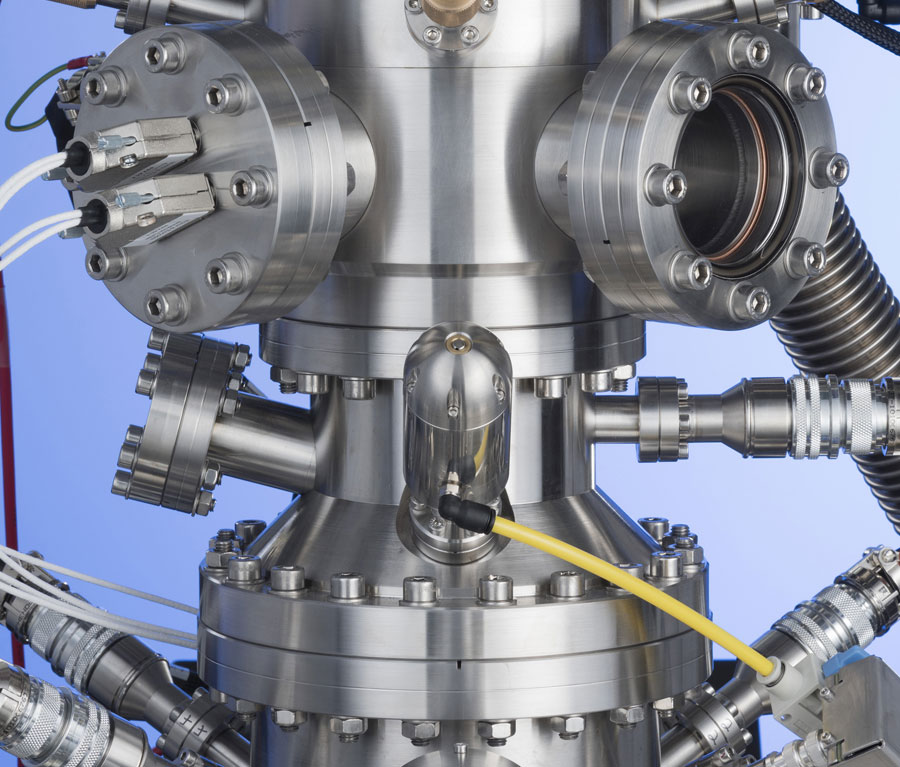

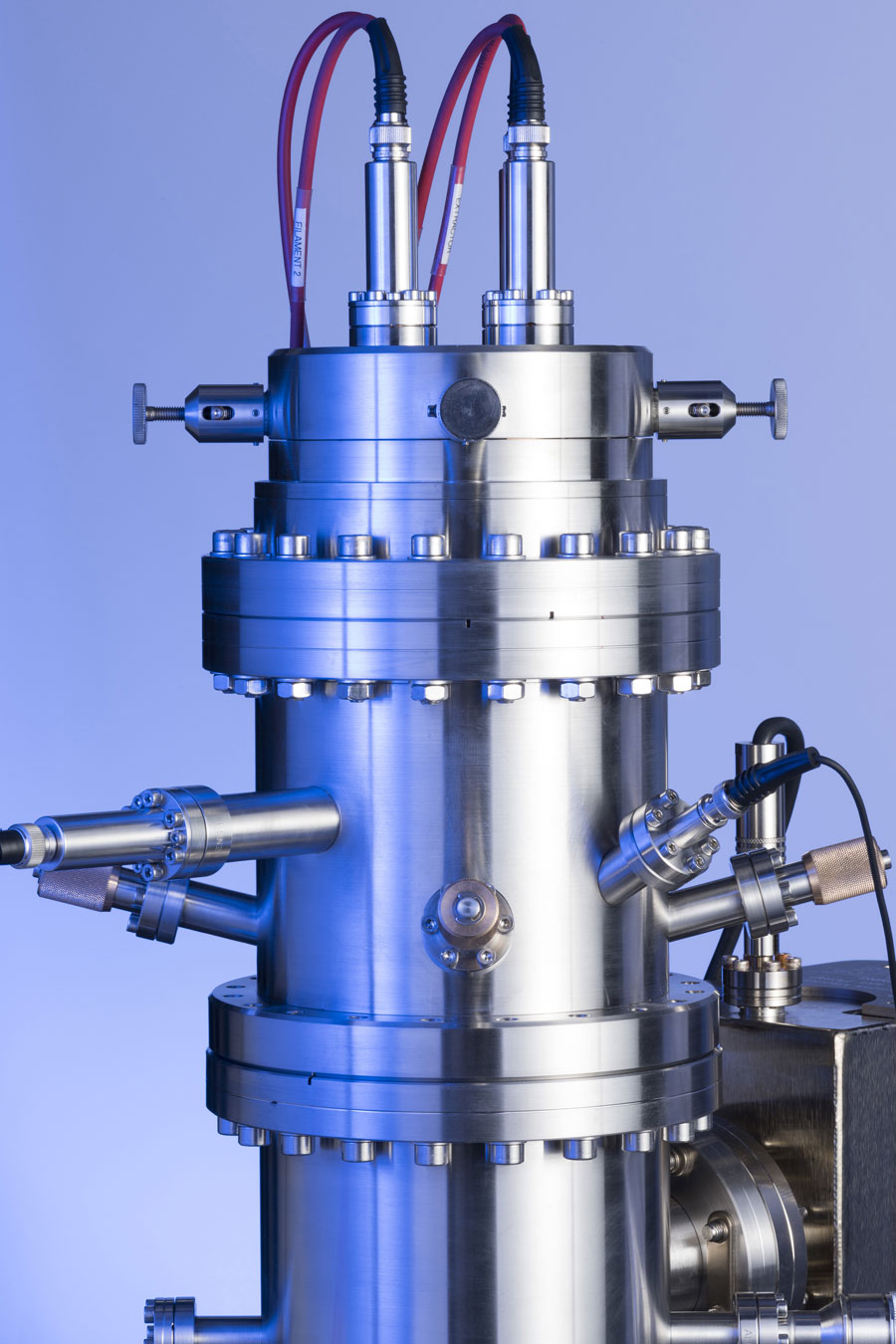

Traditional ion implantation applications would involve implanting vast numbers of ions over a large area to modify the bulk properties of a material. In contrast, Ionoptika’s Q-One is designed to implant single ions with extremely high precision to fabricate quantum devices.

You can learn more about the key benefits of our Q-One system by following the button.

MODIFICATION, GENERATION, AND SELECTION

Ion Implanters

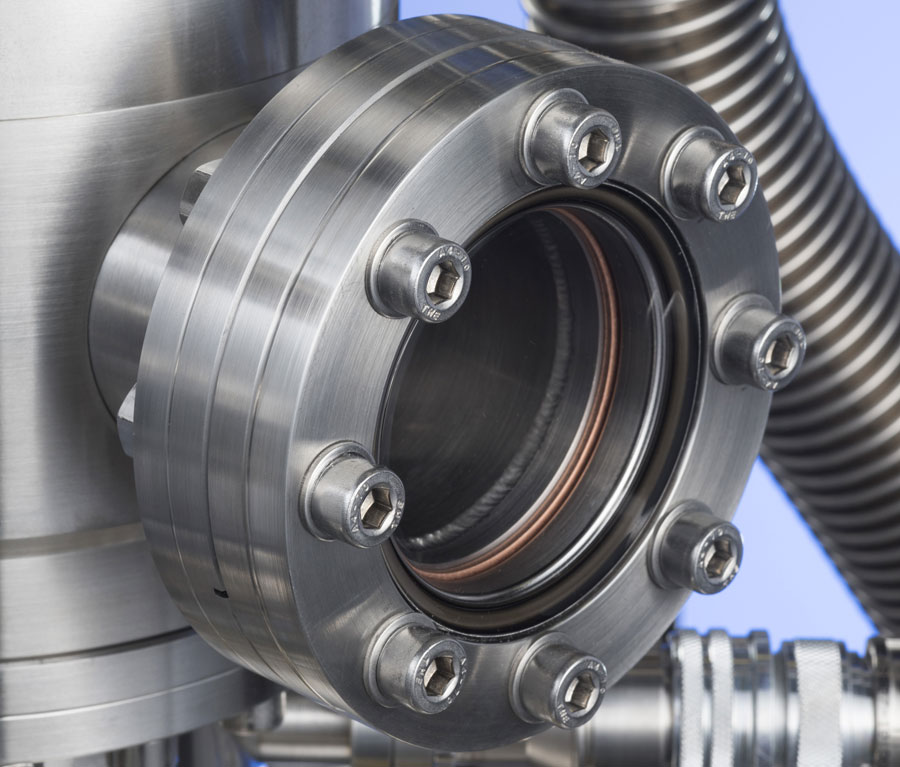

Ion implanters are complex systems used in various applications, consisting of three main components: a source region where ions are generated, an accelerator region that increases the ions’ energy electrostatically, and a target chamber where the ions are implanted. To prevent contamination and electrical breakdown, the entire system must be maintained at a high vacuum.

Ion Generation and Selection

Depending on the design, ion sources can produce multiple ions, including different elements, their isotopes, and various charge states. A magnetic or Wien filter is often employed to select specific ions based on their velocity.

Implanting Species

The choice of implanting species, or dopants, varies widely based on the application:

- Semiconductors: Boron, arsenic, and phosphorus are the most common dopants.

- Metal Processing: Oxygen and nitrogen are frequently used.

- FIBS for Quantum Science: Dopants include phosphorus, nitrogen, silicon, germanium, and rare earth elements like erbium.

Ion Beam Current and System Categorization

Ion implanters are categorized by the Ion Beam current at the target, which can be low, medium, or high. High-current systems, typically used in commercial applications, can operate at tens of milliamps and process hundreds of wafers per hour. By contrast, Ionoptika’s Q-One operates at extremely low currents, often in the range of tens of femtoamps, which is ideal for single-ion implantation.

You can learn more about how our Q-One operates by reading the publications below.

Single Ion Implantation of Bismuth

Nathan Cassidy, Paul Blenkinsopp, Ian Brown, Richard J. Curry, B. N. Murdin, Roger Webb, David Cox

Investigating the formation of isotopically pure layers for quantum computers using ion implantation and layer exchange

Jonathan England, David Cox, Nathan Cassidy, Bobur Mirkhaydarov, Andres Perez-Fadon

Customers across a diverse range of industries have been delighted with the results of our ion implantation and semiconductor services.

PIONEERING CHANGE AND INNOVATION

Ion Implanters

Ion Dose

The ion dose is the accumulated ion current per unit area over time, measured in ions per square centimetre (ions/cm²). This dose determines the dopant concentration within the target. Typical dose values range from 10¹⁶ to 10¹⁸ ions/cm².

Beam Energy and Ion Stopping

The energy of the Ion Beam, a key parameter in ion implantation, influences several critical aspects of the process. This energy, measured in electron volts (eV), is calculated as the product of the accelerator voltage and the ion’s charge state. For instance, a Bi²⁺ ion in a 30 kV field has an energy of 60 keV.

What happens on impact?

Upon impacting the target, ions lose kinetic energy through collisions with the nuclei and electrons in the material until they stop. The penetration depth of the ions is determined by their energy and mass, the target material’s mass, and the beam’s angle relative to the crystal plane for single crystals.

Higher energy levels allow deeper penetration for a given ion mass, while lighter ions penetrate further at the same energy as heavier ions.

How do the instruments operate?

Ion implantation instruments operate within a broad energy range, from 1 keV to several MeV. Ionoptika’s Q-One, for example, operates between 5 and 40 kV, allowing ion penetration to depths of approximately 5 to 100 nm, suitable for most quantum applications.

Ion Straggle

As ions stop, they tend to deviate laterally from their initial path, a phenomenon known as straggle. Straggle is significant in single-ion implantation, where precision is crucial. The accuracy of ion placement depends on the sum of the beam diameter at the target and the lateral straggle. In many cases, the straggle exceeds the beam size, making it the limiting factor in achieving precise implantation.

Straggle is directly proportional to energy and inversely proportional to mass. Therefore, reducing the implantation energy and using heavier elements can enhance precision by minimizing straggle.

Damage from Ion Implantation

Ion implantation is a highly energetic process that can cause significant damage to the target material. The implanted ions transfer a substantial amount of kinetic energy to the target atoms, displacing them from their lattice sites.

This displacement leads to a collision cascade, resulting in various defects, such as vacancies, interstitials, amorphous zones, stacking faults, and dislocation loops.

Post-implantation thermal annealing is essential to restore the crystalline order and ensure proper device functionality. However, high temperatures during annealing can also cause diffusion of the implanted atoms, necessitating careful design of the annealing process.

Sputter Yield

Beam energy also affects the sputter yield, which is the average number of atoms ejected from the target surface per incident ion. If the sputter yield (Y) exceeds 1, more target atoms are removed than implanted, leading to erosion.

If Y is less than 1, fewer atoms are sputtered, and material buildup occurs. When Y equals 1, there is a one-for-one replacement of target atoms with implanted ions.

Understanding these processes and parameters is critical for optimizing ion implantation for specific applications, ensuring precise control over dopant concentration, and managing the associated material effects.