Posts

Ion Beams and their Applications

Ion beams come in many shapes and sizes, with multiple source options and applications. A…

Ionoptika 2020

Ionoptika 2020GCIB-SEM: 3D electron microscopy with < 10nm isotropic resolution

GCIB-SEM is a new technique that combines high resolution electron microscopy with the damage…

Ionoptika 2020

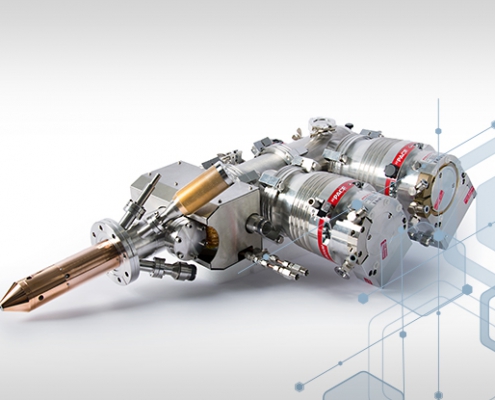

Ionoptika 2020GCIB 10S Webinar in association with UCVAC

On Thursday, in collaboration with UCVAC, we held a webinar on the GCIB 10S Gas Cluster Ion…